Shaped by the constantly evolving demands of defence and maritime industry, we develop and produce solutions for a smarter, safer future. Our achievements are not merely based upon our last two centuries of innovation, but on the close collaboration between customer, design and development. It is in the crux of that cooperation the highest performing solutions come to life. Several of our products endure exposure to open sea for more than 20 years without defects, and will still remain modern even 40 years post-inception. We are able to deliver large scale multi-discipline projects. All the way from an idea, to proof of concept, development, mechanical and electrical production, to the testing and the project management required to make all of this happen seamlessly.

Concept Studies

From a mere idea to finalized innovation; concept studies are a valuable first step in an often difficult process. Giving us the opportunity to trial and model different solutions, and the customer a chance to customize for optimization. We make this process easy, by offering complete project management and everything in between. Deliverables such as drawings, 3D-models, protoypes or project optimalization stragegies are often the name of the game for these projects.

Design and Development

Skilled engineers with a wide range of knowledge and experience, with cutting-edge tools and processes to support creativity at work. Integrated PDM, close decision support, scenario demonstrators and test facilities making each process quicker, safer, and more cost-effective. We split in half to deliver upon our own product series, as well as 'outsource' our expertise to develop customer projects.

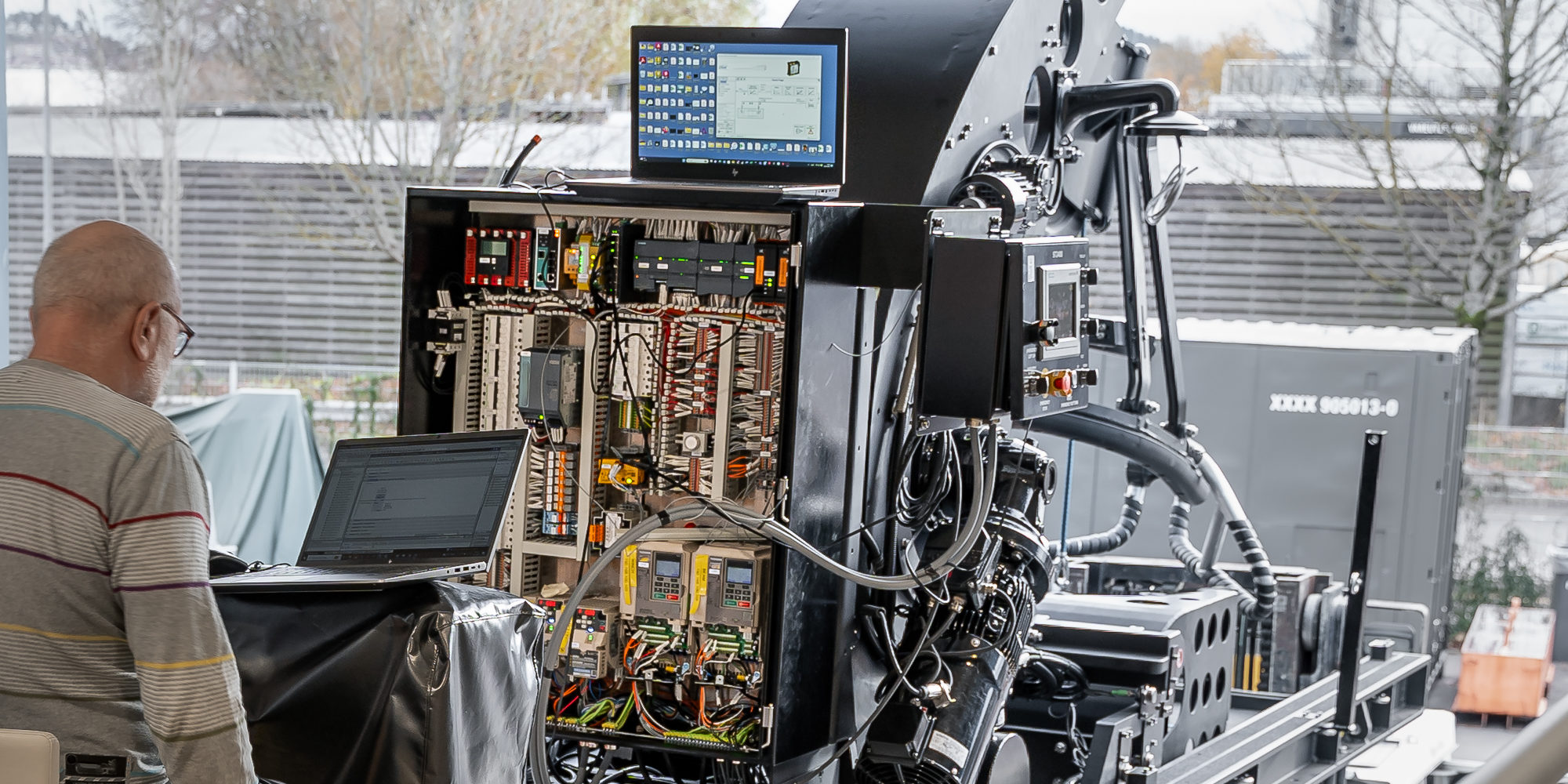

Electronics and Software

To stay on top of the quickly and constantly evolving field of electronic development. We had to gather a team of engineers dedicated to solely focus on pushing the boundaries for whats possible with the latest avaliable technologies. We develop electronic solutions and software from the ground up. We strive to do things a little differently, and ensure our electronics systems exceed our high standards and long lifetime requirements.

Production

We work with external experts and sub-suppliers to producte at scale. However, we like to keep the final touch of our products in-house. We either produce or control check everything from large machinery to tiny components, and rely on out scalable production facilities. You will find assembly-lines for mechanical, welding, machining, electrical, and hydraulic production all in-house.

Testing and Certifications

We have produced lifting and climbing equipment for a century and have facilitated for the international requirements securing such production. A central component in our vision relies on our thorough testing and verifications, with or without 3rd party auditors. Our test facilities are as such well-integrated and of proven efficacy.

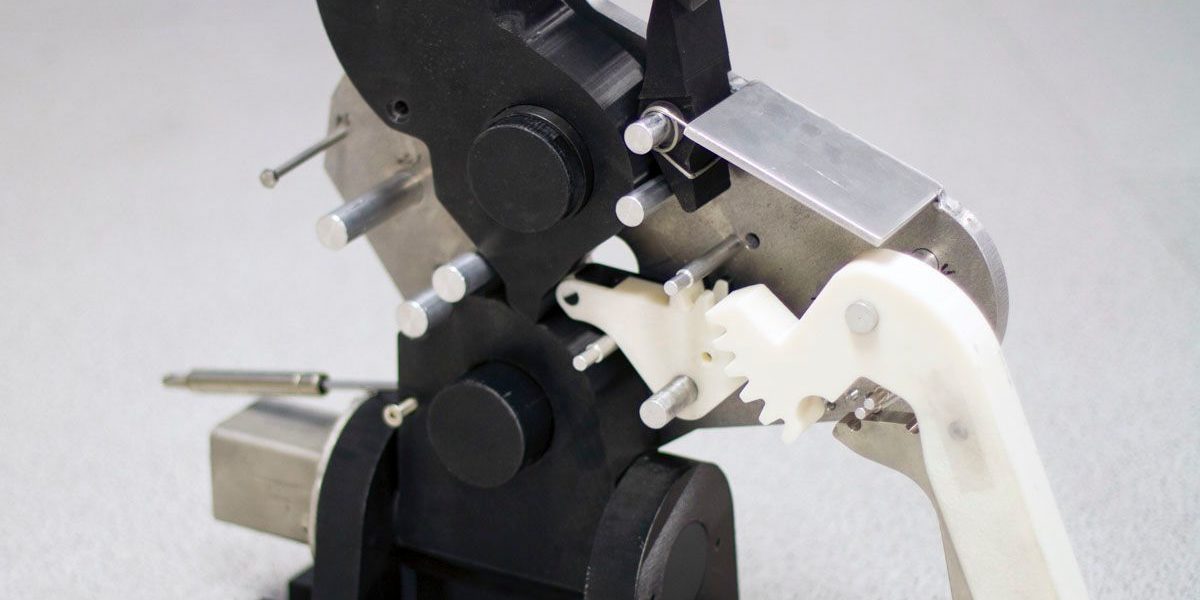

Rapid Protyping

Rapid prototyping is a crucial tool to move fast during the development phase. Our top of the line 3D printers are always at work, producing samples in order for customers and engineers to do hands-on fit-form analysis. These printers and other tools have boosted our processes, and makes it easy for customers to evaluate drawings or 3D models. Resulting in fewer hiccups along the route, and further optimizations ahead of production.

Turnkey Solutions

A large part of our deliverables are turn-key ready projects. One or a few customized products delivered at site. Starting with an idea creation or a finalized spec, we seek to apply expertise and innovation where needed and make it as easy as possible to put our solutions and systems to use.

Service

Some products and solutions have requirements for periodic service maintenance. We have a dedicated team of experts and integrated digital solutions for customer support. On many deliverables we offer instant replacement-products, meaning you can call for a refurbished item when service is due, replace it, then return the product due for service. Finished in one operation with no downtime.